The dyeing process of reactive dyes is divided into two parts: dyeing and fixation.

Dyeing process: This is the initial stage of dyeing. During dyeing, the circulating flow of dyeing solution causes the relative movement between the dyeing solution and the fiber surface. The flow rate of dyeing solution decreases continuously to zero when it is close to the fiber surface. This liquid layer with zero flow rate is the dynamic boundary layer. Increasing the flow rate of dyeing solution can reduce the thickness of dyeing dynamic boundary layer on the fiber surface and increase the dyeing speed of dye.

After the dye moves from the main body of the dye solution to the outside of the dynamic boundary layer, the diffusion speed gradually decreases until the flow speed is lower than its own diffusion speed. The dye approaches the fiber surface through diffusion. The dye is in the diffusion boundary layer in this process. Increasing the flow rate can reduce the thickness of the diffusion boundary layer and increase the adsorption speed of the dye on the fiber surface. The dye moves towards the fiber surface in the diffusion boundary layer until it reaches the distance of molecular force, and then it is quickly adsorbed on the fiber surface, separated from the dye solution and transferred to the fiber surface.

At the beginning of dyeing, there is a high concentration difference between the surface of the dyed fabric and the dye solution. The fiber adsorbs the dye faster. With the concentration difference gradually decreasing, the dyeing rate slows down, and gradually reaches the dynamic balance of adsorption and desorption. The affinity of the dye is large and the dye solution concentration is high. The dye adsorbed to the fiber surface diffuses internally due to the concentration difference with the fiber. During the dyeing process, there are many tortuous and penetrating aqueous solution channels in the cotton fiber. The water molecules in the dye solution swell the fiber and increase the pore diameter. Under the action of concentration difference, the dye molecules diffuse into the fiber through the pore or adsorb on the pore wall.

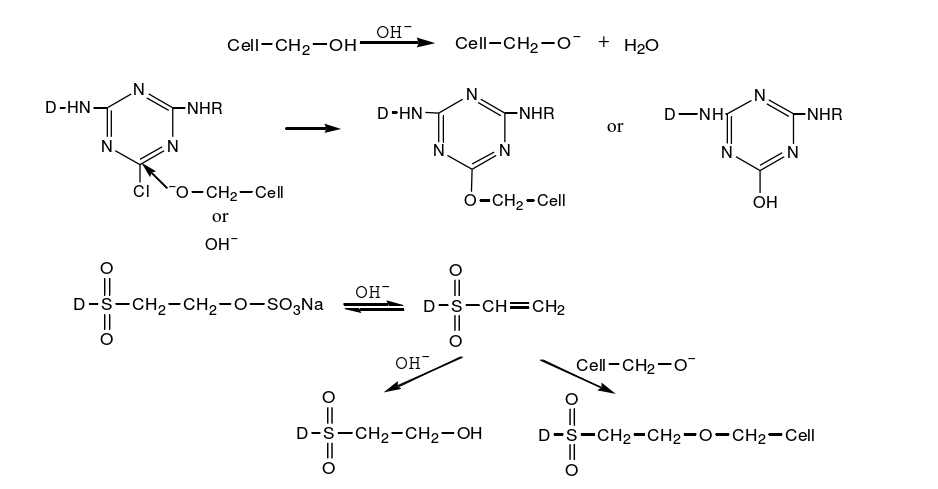

Fixation process: the neutral substance of cellulose fiber is relatively stable in general neutral medium. In alkaline medium, cellulose anion can be ionized to form cellulose anion and then react with reactive dyes. Therefore, alkali agent needs to be added in the fixation process. After the dye diffuses onto the fiber, the nucleophilic reagent cellulose anion attacks the active group of the reactive dye under alkaline conditions, and then reacts with the active group to form ester bond or ether bond, as shown in the figure. The nucleophilic reaction between oh and reactive dye can also occur in the hydrolysis process.