Mercerized cotton is the best of cotton. The fabric takes cotton as raw material and is made into high-quality mercerized yarn through worsted spinning, and then made into smooth, bright, soft and wrinkle resistant high-quality mercerized yarn through special processing procedures such as singeing and mercerization. The high-quality knitted fabric made of this raw material not only completely retains the excellent natural characteristics of raw cotton, but also has silk like luster and soft feel.

1.Difference between mercerized cotton and pure cotton

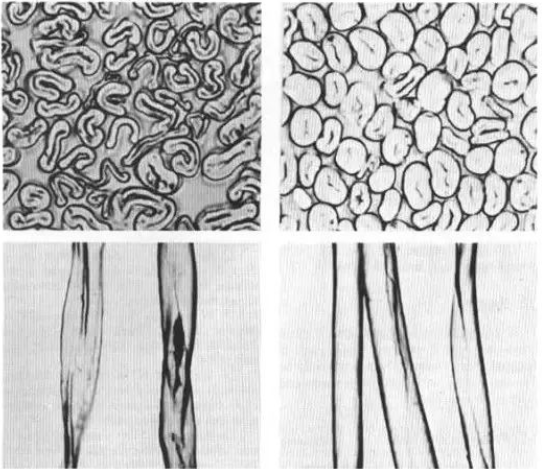

① The cross section of pure cotton is waist round, and the cross section of mercerized cotton is round.

② The longitudinal section of pure cotton has natural distortion, and the wrinkles on the surface of mercerized cotton disappear and become smooth.

Physical property

① Mercerized cotton has better luster than pure cotton (the surface is smooth after mercerization and has less diffuse reflection of light);

② The strength of mercerized cotton is higher than that of pure cotton (the natural distortion disappears, the fibers are closely arranged and the holding force increases);

③ The dimensional stability of mercerized cotton is higher than that of pure cotton (rearrangement of cellulose molecules and elimination of original internal stress).

Chemical properties

① The reactivity of mercerized cotton is improved (the amorphous region increases, and the hydroxyl group changes from inaccessible to accessible with the rotation of the main valence bond);

② The adsorption capacity of mercerized cotton to water, iodine, barium hydroxide and dyes is greater than that of pure cotton.

2.Properties of mercerized cotton

Morphological structure

The fiber diameter increases and becomes round, the longitudinal natural twist rate changes (80% → 14.5%), the cross section changes from waist to ellipse, even round, and the cell cavity shrinks to a little.

If the fiber is properly applied, the smoothness of the fiber surface will be improved, and the original optical strength will be improved.

The change of fiber shape in the fabric is the main reason for the luster, and the tension is the main factor to improve the luster.

Microstructure

Crystallinity ↓ (70% → 50%) and amorphous area ↑ make the hydroxyl groups that were not accessible in water accessible, so the adsorption and chemical reaction properties of the fiber to dyes are improved;

After mercerization, the fiber morphology changes and the light scattering on the surface and inside decreases. Therefore, when dyeing with the same concentration of dyes, the dyeing depth also increases.

After the fiber swells, the hydrogen bonds between macromolecules are broken down. Under the action of tension, the arrangement of macromolecules tends to be neat, which improves the degree of orientation;

The uneven deformation of the fiber surface is eliminated and the weak links are reduced. So that the fiber can evenly share the external force, so as to reduce the fracture phenomenon caused by stress concentration. In addition, the fibers after expansion and rearrangement are close to each other, and the holding force also reduces the factors of fracture caused by macromolecular slip.

Changes in molecular structure

After cotton fiber swells in concentrated alkali solution, the hydrogen bond between macromolecular chains is broken down, which relieves the internal stress stored in the fabric. Through stretching, macromolecules are oriented and arranged, and new molecular bonds are established in new positions, and the intermolecular force is greater than that before swelling. Finally, under tension, the hydrogen bond between the oriented fibers is fixed. At this time, the fibers are in a low energy state, so the size is stable.

3.Characteristics of mercerized cotton

Due to the expansion of fibers, the fibers are arranged more neatly and the reflection of light is more regular. Thus enhancing the luster.

After mercerization, the crystal area of the fiber decreases and the amorphous area increases, while the effect of fuel and other chemicals on the fiber occurs in the amorphous area. Therefore, the dye uptake and the chemical reaction performance of the fiber are improved after mercerization.

In the mercerization process, the arrangement of fiber macromolecules tends to be neat, the degree of orientation is improved, the uneven deformation of fiber surface is eliminated, and the weak links are reduced. When subjected to external force, more macromolecules can share evenly, the primary fracture strength increases and the fracture elongation decreases.

Mercerization can be used to eliminate rope creases and better meet the quality requirements of dyeing and printing for semi-finished products. More importantly, after mercerization, the stability of fabric expansion and deformation has been greatly improved and the shrinkage of fabric has been greatly reduced.